BOY-WF06-TR Doppler flowmeter

Product features:

1. Integrated design, built-in a variety of sensors measurement data.

2. Wide applicability, can work in non-standard section, low flow rate, low liquid level conditions.

3. No mechanical rotor structure, does not disturb the flow field, flow state.

▋ Video Description

▋Product Description

BOY-WF06-TR Doppler flowmeter is used in river, open channel and pipeline and other conditions of the flow rate detection instrument. It adopts ultrasonic detection technology, high measurement accuracy, high stability, little affected by environmental factors, no rotating parts, low maintenance frequency, high reliability, is the first choice for online measurement and portable measurement products.

▋ Product Parameter

| Parameter | Description |

| Velocity range | 0.021m/s~6.00m/s |

| Velocity resolution | 0.001m/s |

| Water level range | 0.03m~10m |

| Water level resolution | 0.001m |

| Water temperature range | 10°C~60°C |

| Water temperature resolution | 0.1°C |

| Emission frequency | 2MH2 |

| Output | RS485 |

| Power supply voltage | 4~28VDC |

| Protection level | IP68 |

| Standby current | 0.14W |

| Operating current | 0.8W |

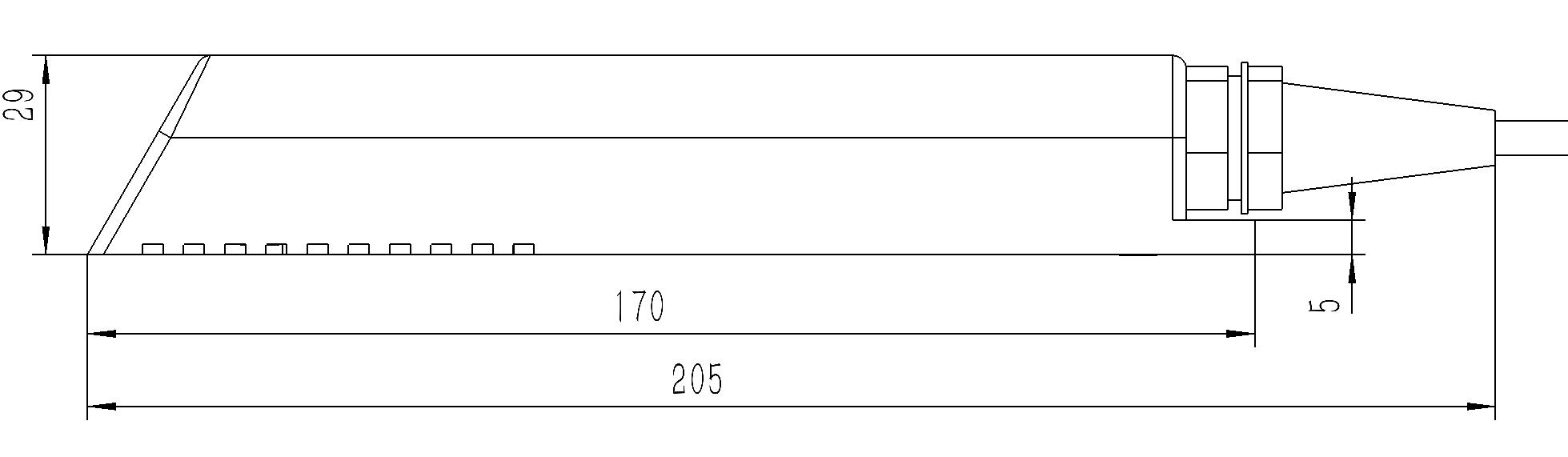

| Dimension | 170*50*29mm |

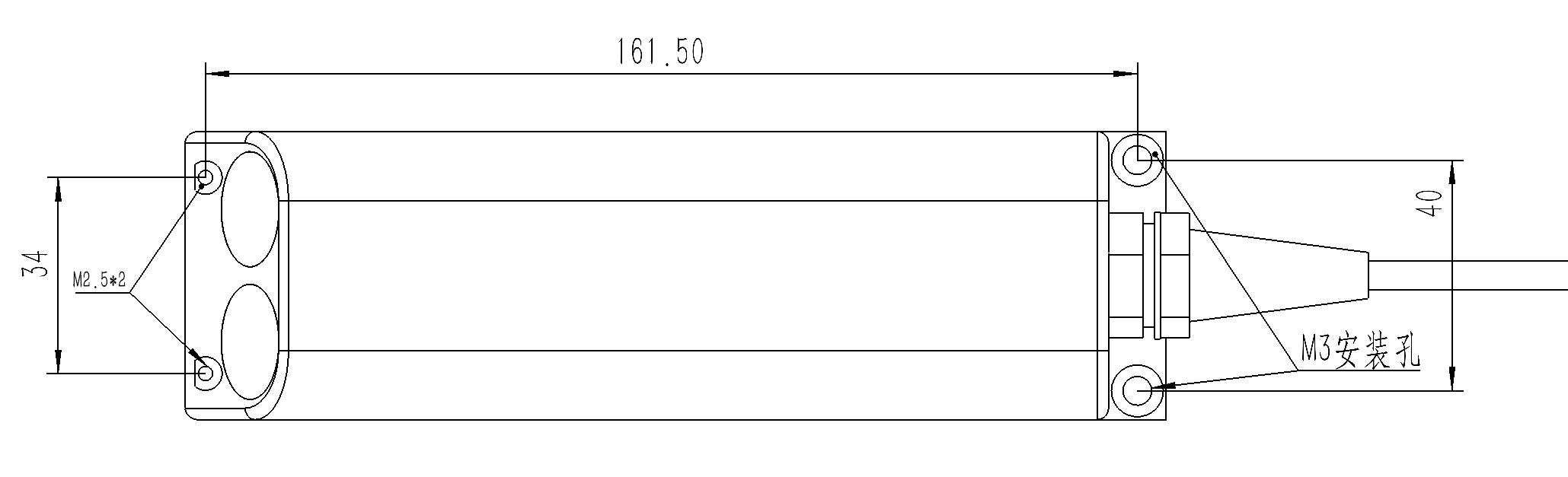

▋ Product size

▋ Working Mechanism

BOY-WF06-TR Doppler flowmeter uses the Doppler effect of sound waves propagating through the fluid to measure tiny particles in the fluid. The velocity of the fluid is measured by the Doppler shift generated by the scattering of sound waves by particles and bubbles. Combined with built-in diffused silicon. The liquid level data provided by the pressure sensor is used to measure the flow rate of the fluid by the velocity area method.

Attention Item:

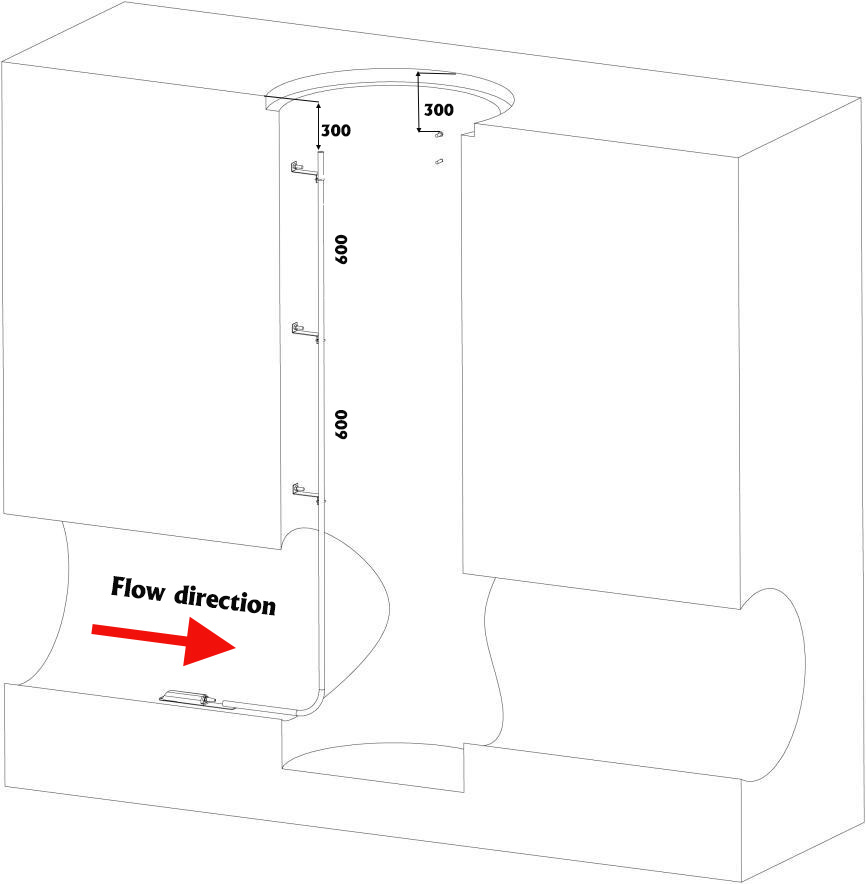

1. The Doppler flowmeter should be installed horizontally at the bottom of the pipe, while ensuring that it is parallel to the direction of the water flow and is consistent with the sensor.No barrier at the end shall interfere with the flow pattern; In special cases, such as the sludge at the bottom of the pipeline cannot be removed.Consider elevating the equipment to avoid silting.

2. the pipe network water is large and not easy to plug the equipment installation point, the sensor can be installed in the pipe bracket.Carry out monitoring and fix the support to the well wall.

▋ Application

1. Sudden drop in signal strength

Solution: Clean the probe with a soft bristled brush and pH 7 cleaner, avoiding the use of alcohol; Check if the cable joints have water ingress and install waterproof junction boxes; Check the stability of the power supply.

2. Low signal strength

Solution: For situations where the pipe diameter is too large or scaling is severe, an insertable probe can be used, or the installation position can be re selected.

3. Periodic jump of data

Solution: Enable the "Dynamic Smoothing Algorithm" and set a 3-5 minute moving average window; Spectrum analysis locates the interference source and switches to the anti-interference frequency band.

4. Inaccurate measurement data

Solution: Regularly clean the sensor, adjust the sensor position, and recalibrate the instrument.

5. Data permanent offset

Solution: Use a laser locator to verify the installation angle and input new parameters into the signal processor.

6. Unable to start or difficult to start

Solution: Check the power supply wiring to ensure that the power supply voltage is stable and meets the equipment requirements; If the power supply is normal, it needs to be checked by professional personnel