BOY-YP04-S Pressure Transmitters

Product features:

1. Wide range, optional output signal, with LCD display.

2. High stability, lightning proof, shock proof, explosion proof.

3. High cost performance, small size, beautiful appearance.

▋ Product Description

BOY-YP04-S has strong anti-interference, overload and impact resistance, small temperature drift, high stability, and high measurement accuracy, and is the ideal pressure measuring instrument in the field of industrial automation.

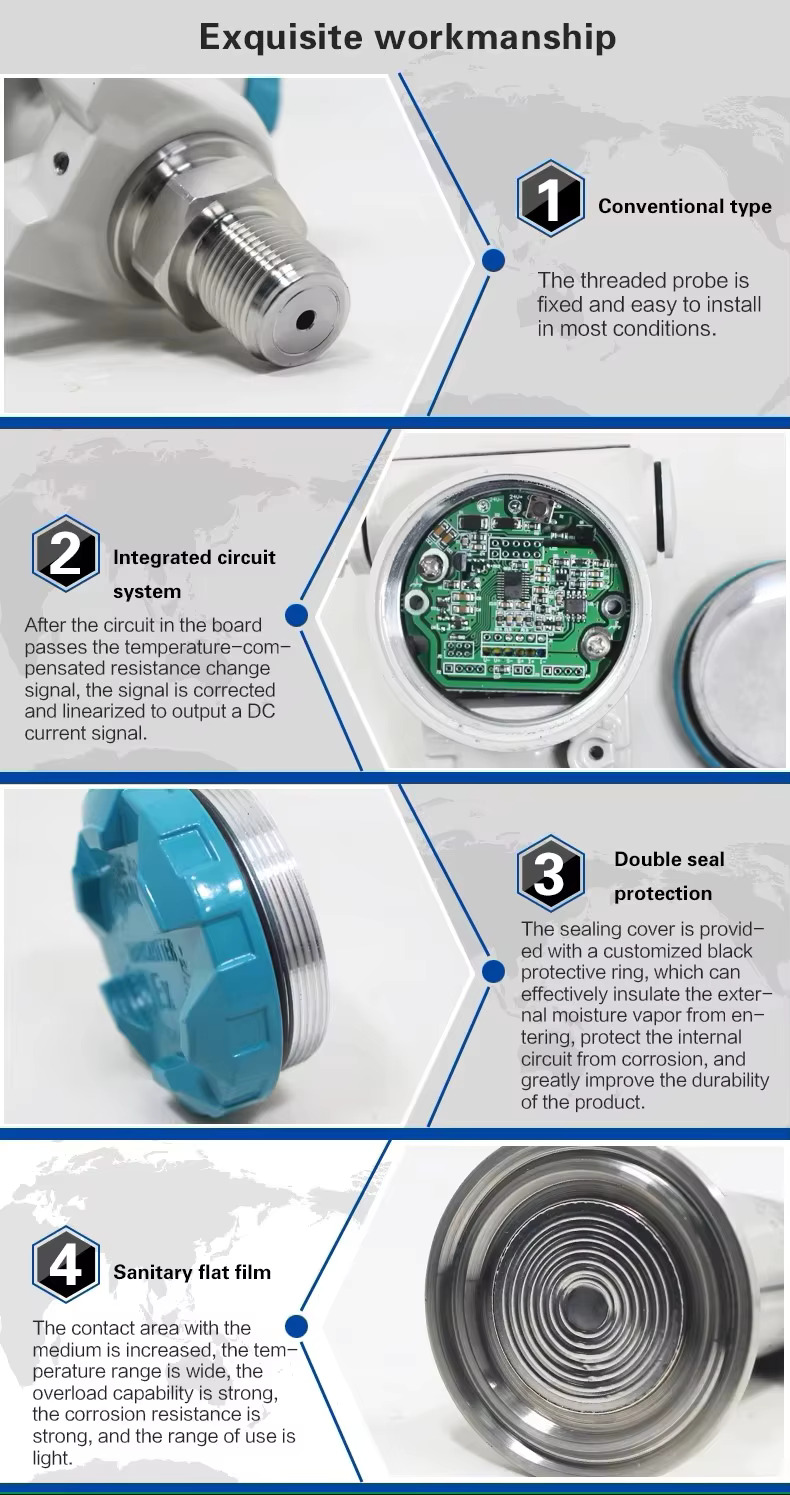

▋ Product Details

▋ Product Parameter

| Parameter | Index |

| Pressure Range | -100kPa~0~100MPa |

| Accuracy | 0.1%FS ,0.25%FS, 0.5%FS |

| Overload capacity | 200% full scale |

| Output | 4~20mA,4~20mA HART,RS485,0~10VDC,0~5VDC, 1~5VDC |

| IP grade | IP66 |

| Material | Aluminum,Stainless steel |

| Power supply | 12~36VDC |

| Stability performance | ±0.1% FS/Year |

| Operating temperature | -40℃~85℃ |

▋ Measurement Method

BOY-YP04-S uses the OEM pressure sensor with stainless steel isolation diaphragm as the signal measurement element, and through the computer automatic test and compensation calculation, the amplifier circuit is located in the housing, the sensor signal is converted to the standard output signal, with excellent performance.

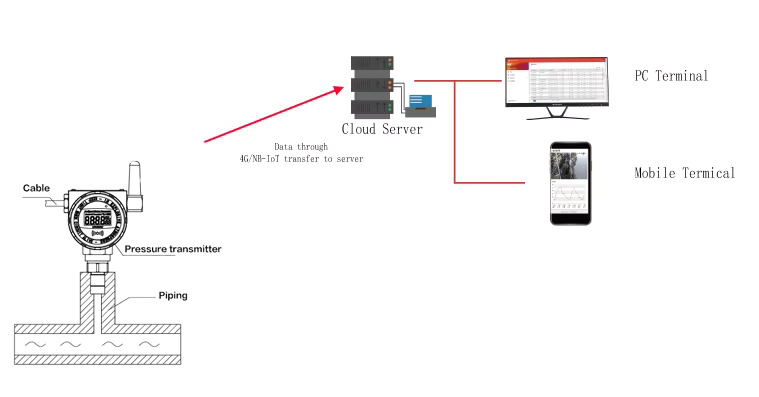

▋ Installation Method

Note;Shielded twisted-pair signal cables are recommended. To avoid grounding loops, the shield is single-ended grounded, insulated at the pressure transmitter end and grounded at the control cabinet end.

▋ Application

▋ FAQ

1. No output is displayed

First check whether the power supply is normal and whether the power cable is properly connected. If the power supply is normal, further check the measurement circuit and output signal to determine whether there is an open or short circuit. If there is no problem with the above checks, the pressure sensing element may be damaged and needs to be replaced.

2. The output is abnormal

It may be due to blockage or corrosion of the pressure sensing element. At this time, it is necessary to check the installation position of the transmitter and the measurement medium to ensure that no impurities and particles enter the measurement chamber. At the same time, check whether the temperature and viscosity of the measured medium are within the normal range.

3. Zero offset

Zero offset means that the output value of the pressure transmitter is not zero under no pressure. This may be due to improper adjustment of the measurement circuit or accumulation of errors in the sensing element. For this fault, it is necessary to readjust the zero position and range of the measuring circuit, and calibrate the sensing element.

4. Range drift

Range drift means that the output value of the pressure transmitter changes over time, which may be due to aging of the pressure sensing element and temperature drift. For this kind of failure, the transmitter needs to be calibrated and maintained regularly, and attention is paid to the temperature changes in the environment in which it is used.

Recommend

Online Service

Online Service