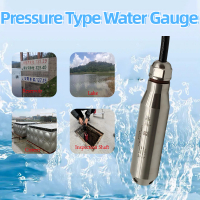

BOY-WR04-S Pressure type water level gauge

Product features:

1.Sensitive response: the use of A class diffused silicon pressure sensitive elements

2.Easy installation: cable connection, directly into the site

3.Good stability: the amplifier circuit uses the United States integrated chip, wide voltage power supply, reverse wiring and overvoltage protection

4.Srong anti-interference ability: anti-lightning, intercept interference design

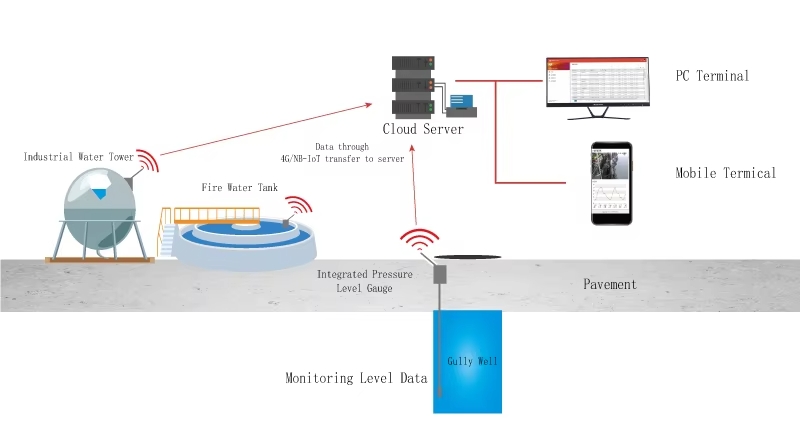

▋ Product Description

BOY-WR04-S pressure level gauge uses OEM pressure sensor with stainless steel isolation diaphragm as signal measurement element, and is automatically tested by computer. The zero point and sensitivity temperature compensation are carried out in a wide temperature range by laser resistance adjustment process. The amplifier circuit is located in the dry stainless steel housing and converts the sensor signal to the standard output signal. The pressure type water level gauge has the advantages of anti-interference, small temperature drift, high measurement accuracy, good stability and long life. Widely used in river, reservoir, groundwater, water supply and drainage, sewage treatment and other water level monitoring.

▋ Main Function

Function | Description |

Water level collection | Collection period The water level is collected periodically |

Data transmission | Data is sent over RS485 |

▋ Product Characteristics

BOY-WR04-S pressure water level gauge has the advantages of anti-interference, small temperature drift, high measurement accuracy, good stability and long life.

|

|

|

Responsive | Easy to install | Good stability |

Grade A diffused silicon pressure sensor is used | Cable connection, put directly into the field | The amplifier circuit adopts the American integrated chip, Wide voltage supply, reverse wiring and overvoltage protection |

|

|

|

Strong anti-interference ability | Fast response speed | Current limiting protection |

Lightning protection, cut frequency interference design | Amplifier circuit adopts imported integrated chip, wide voltage power supply | Wiring reverse and overvoltage protection |

▋ Product Parameter

Water level parameter | |

Measuring medium | Liquid (compatible with contact material) |

Measuring range | 0 ~ 10m (customizable) |

Accuracy level | 0.1%FS, 0.25%FS, 0.5%FS |

Working condition | Medium temperature -40 ~ 85℃ |

Temperature compensation | -10 ~ 70℃ |

Stability performance | ±0.1% FS/ year |

Overload capacity | 200% full scale |

Temperature drift | ±0.01% FS / ℃ |

Environmental parameter | |

Supply voltage | 12-36VDC |

Ambient temperature | -40 ~ 85℃ |

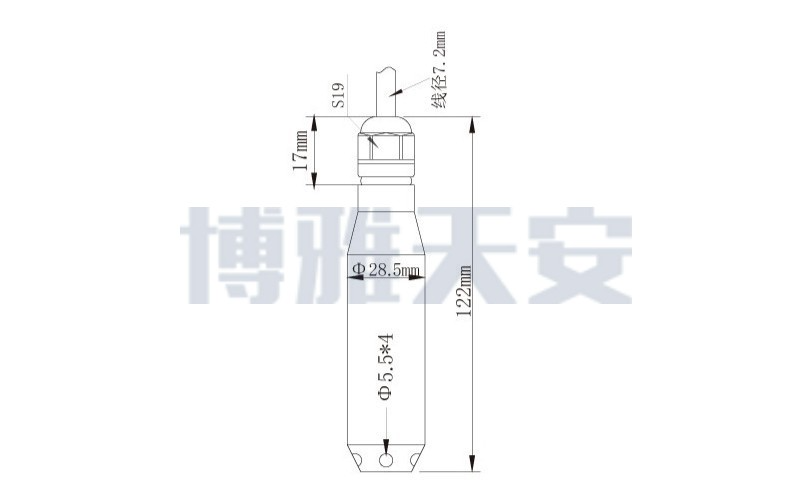

Physical characteristics | |

Overall weight | Probe ≈290g, cable ≈60g per meter |

Class of protection | IP68 |

Interface type | |

Power interface | Industrial grade terminal interface with built-in power reverse protection and overcurrent/overvoltage protection |

Serial port | 1 group of RS485 ports |

Data bits: 5, 6, 7, 8 bits Stop bits: 1, 1.5, and 2 Check: none check, odd check, even check Serial port rate: 1200-115200 BPS | |

▋ Product Size

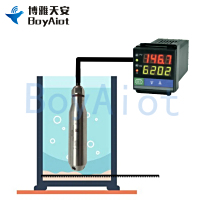

▋ Measurement Method

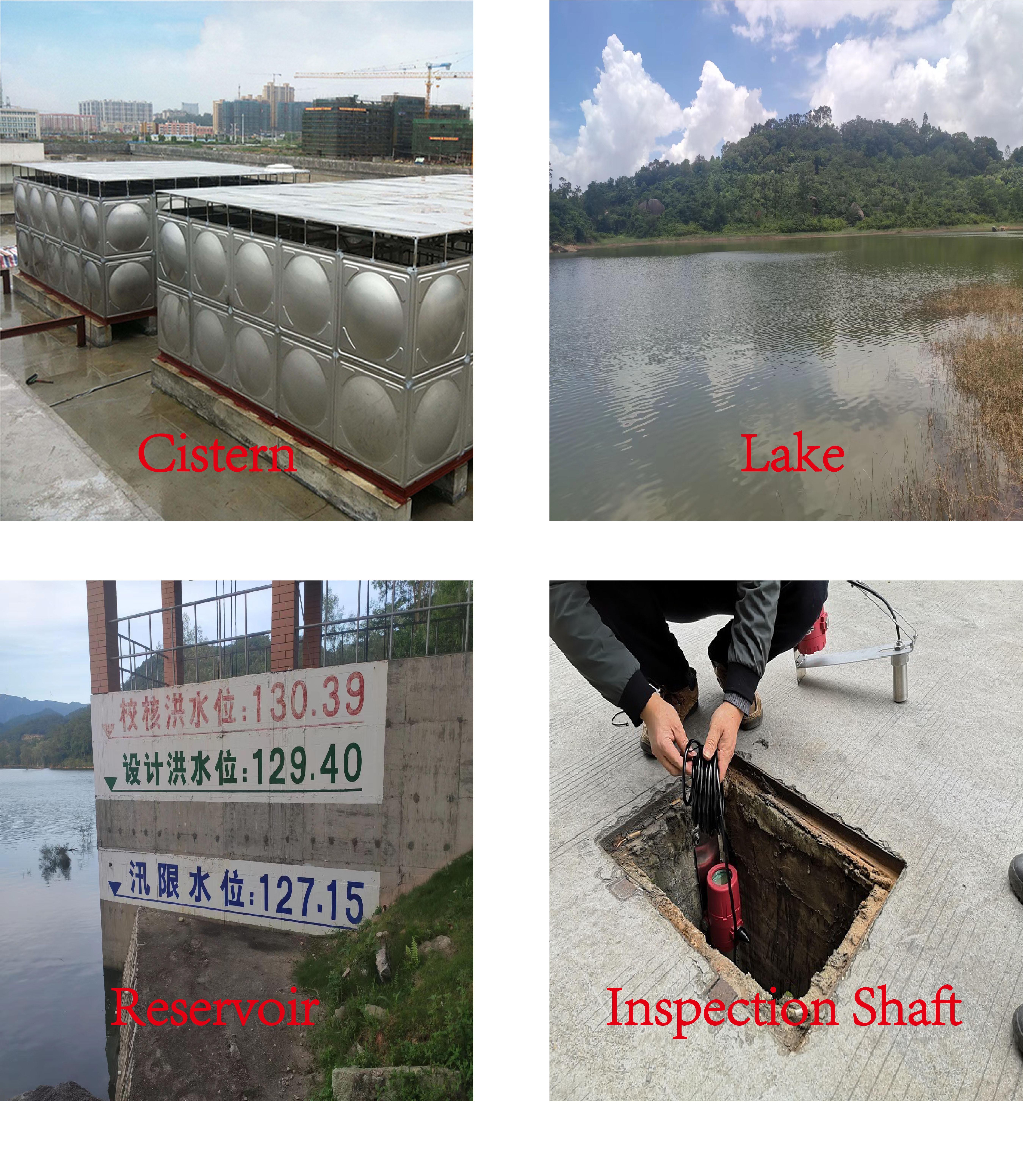

BOY-WR04-S The pressure type water level gauge has the advantages of anti-interference, small temperature drift, high measurement accuracy, good stability and long life. Widely used in river, reservoir, groundwater, water supply and drainage, sewage treatment and other water level monitoring.

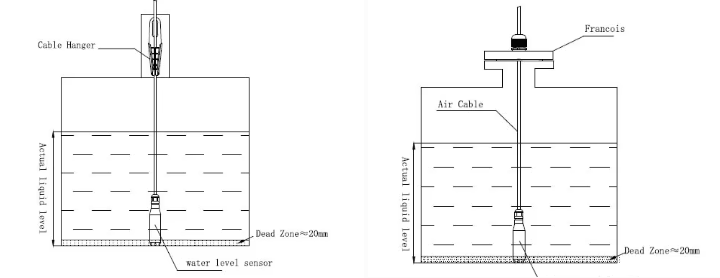

▋ Installation Method

When the liquid level fluctuation is large, measures should be taken to fix the probe part of the liquid level gauge, you can insert or install a steel pipe or PVC pipe larger than the diameter of the probe in the water, and open a number of φ5mm holes in the pipe at different heights in the opposite direction of the water flow, so that water can enter the pipe.

▋ Application

Applicable to: water plant, oil refinery, chemical plant, sewage treatment plant, high-rise water supply system for water supply pool, distribution pool, water treatment pool, municipal rain sewage well, water tank, water tank, oil tank, oil tank and other liquid static and dynamic level measurement.

▋ FAQ

1. Equipment measurement principle?

A: When the sensor is put into a certain depth of the measured liquid, the pressure of the measured medium is introduced into the positive pressure chamber of the sensor, and the atmospheric pressure on the liquid surface is connected to the negative pressure chamber of the sensor through the cable airway to offset the front of the sensor, so that the sensor can measure the pressure, and the liquid level depth can be obtained by measuring the pressure

2. What is the range of the equipment?

A: The default measuring range is 0 ~ 10 meters, and the larger measuring range needs to be customized.

3. What is the measuring accuracy of the equipment?

A: The measurement accuracy is not higher than 0.5%, such as 10 meters range, the accuracy is 5cm.

4. Can the equipment be waterproof? Will water flooding damage the equipment?

A: Can be waterproof, equipment IP68 protection level.

5. Device communication method? What communication protocols are supported?

A: Supports RS485 communication and Modbus communication.

Recommend

Online Service

Online Service