BOY-SW05 Magnetostrictive water gauge

Product features:

1. Wide range of application: non-contact measurement, no friction and wear, long life, suitable for field unmanned environment applications.

2. High reliability, glue sealing, IP68 protection grade, corrosion resistance.

3. Easy installation: easy installation, low operation and maintenance cost.

▋ Product Description

The BOY-SW05 is based on the principle of magnetostrictive measurement and can continuously and accurately measure the height of the liquid level. This series of magnetostrictive electronic water gauge has high measuring accuracy, convenient installation and no regular maintenance and calibration. Suitable for accurate measurement of various liquid levels.

▋ Product Parameter

| Parameter | Description |

| Measuring accuracy | ±2mm |

| Resolution | 0.5mm |

| Output signal interface | RS485 (Modbus protocol) |

| Communication protocol | Modbus-RTU |

| measurement range | 0 ~ 3000mm |

| Power supply | 7-24V/DC |

| Working current | 15mA |

| Resting current | 3mA |

| Measuring temperature | -10℃ ~ +50℃ (no icing) |

| Protection class | Slave IP68 |

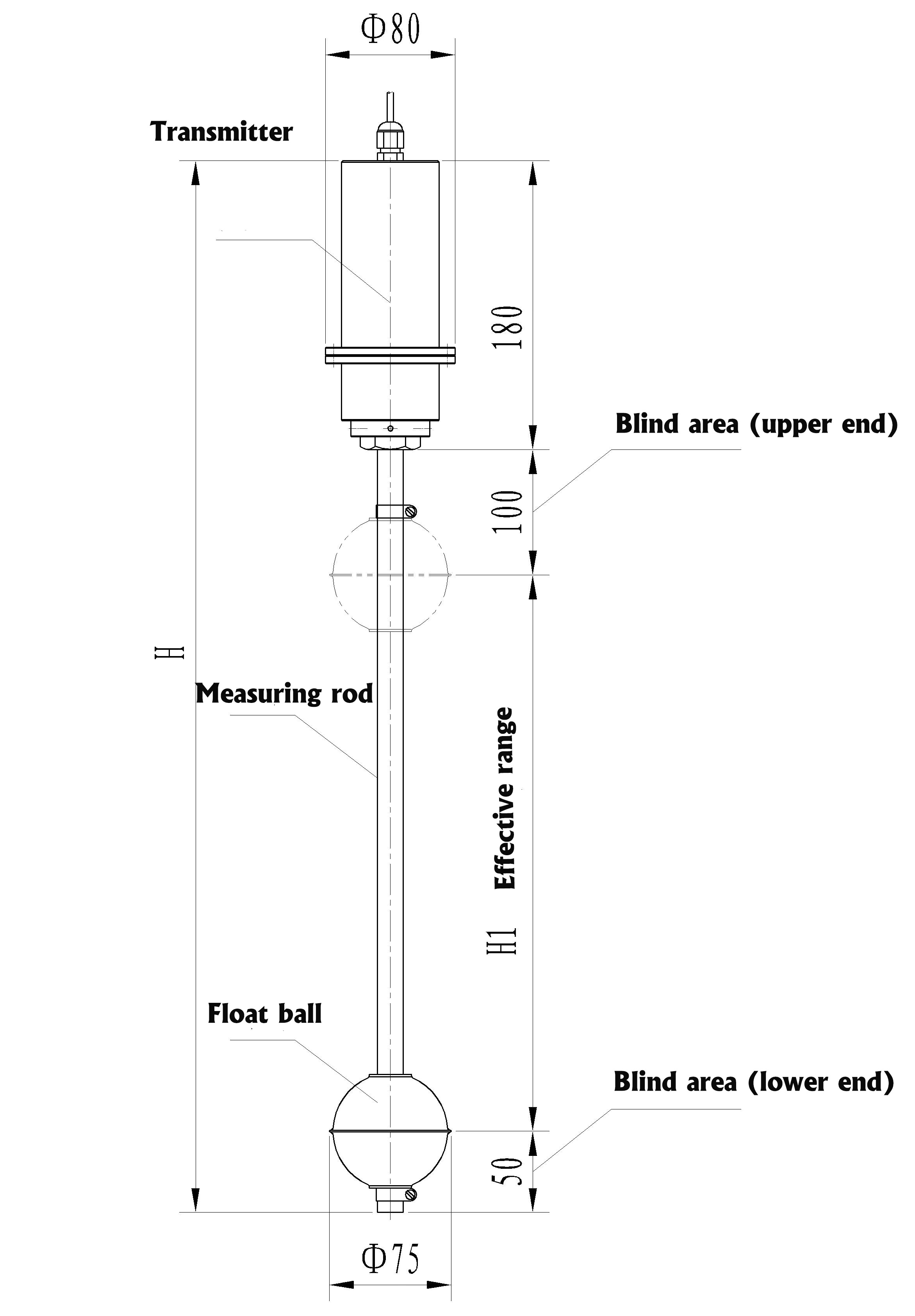

▋ Product Size

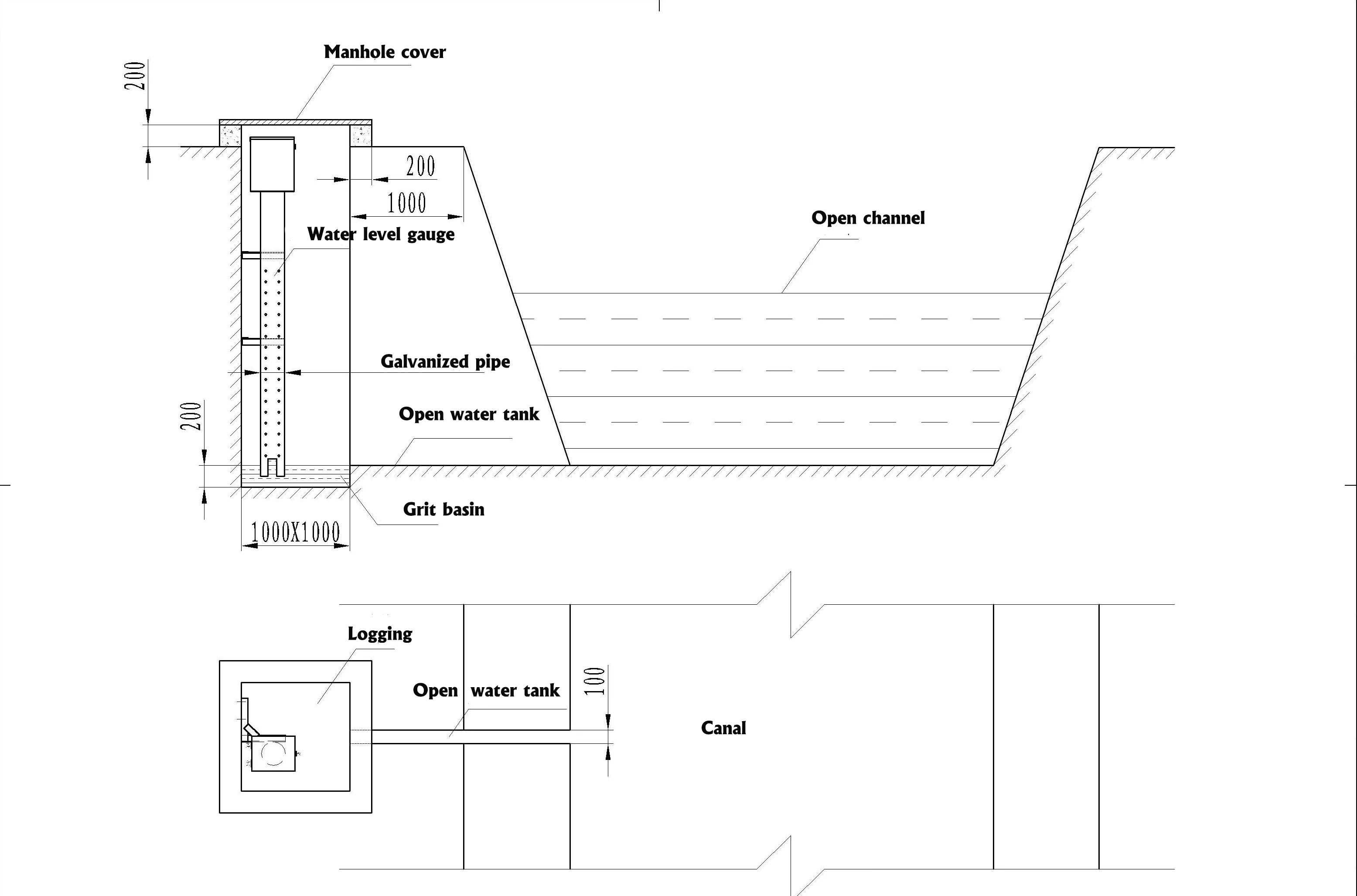

▋ Measurement Method

When the device is working, the signal processing unit sends out an inquiry current pulse to generate a circular magnetic field. A float is provided outside the sensing probe. The float contains a set of permanent magnets that create a magnetic field. According to the interval time between the "return" pulse and the inquiry current pulse, the actual position of the float is calculated, so that the liquid level can be accurately measured.

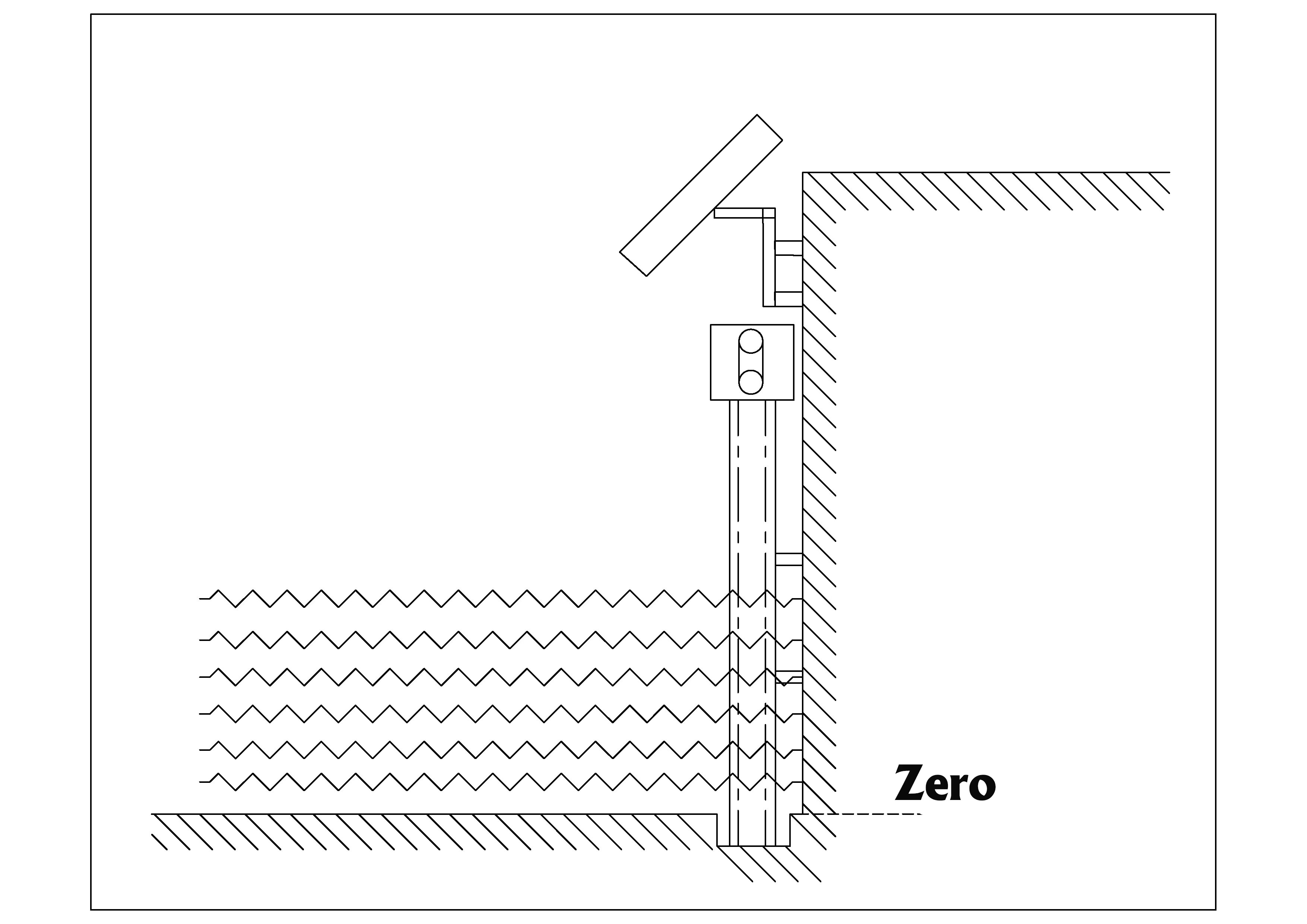

The installation methods of the electronic water gauge are divided into installation without logging and installation with logging. If there is no logging, the equipment can be mounted on the wall and fixed. If there is logging established on the site, the electronic water gauge can be put into the logging.

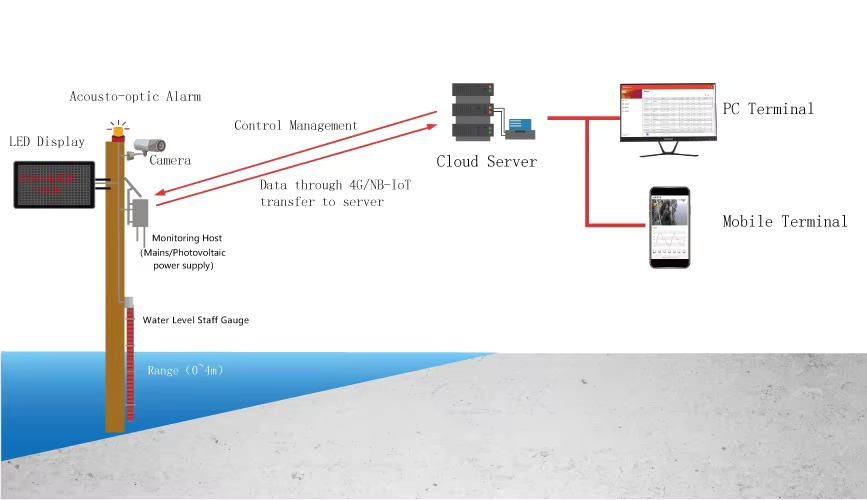

▋ Application

▋ FAQ

1. Inaccurate reading

This may be due to aging or damage to the magnetostrictive element. Damaged magnetostrictive components need to be replaced in time. The magnetostrictive level meter also needs to be calibrated regularly to ensure the accuracy of its measurements.

2, Magnetostrictive level meter leakage

This may be due to aging or damage to the seal. Inspect and replace aging or damaged seals to ensure good sealing performance. It is also necessary to perform regular maintenance on the level gauge to extend its service life.

3. The signal of magnetostrictive level meter is unstable.

This may be caused by unstable power supply or poor contact of signal lines. Ensure that the power supply is stable and signal lines are properly connected.

Recommend

Online Service

Online Service